Tips for using crane hooks

The crane hook is the most commonly used lifting device in lifting operations. It bears the entire load of the lifting. If it is not inspected daily, it may be damaged or not fixed securely, which can easily cause safety accidents.

I. What are the types of crane hooks?

There are many types of hooks. Generally speaking, they can be divided into forged hooks and laminated hooks according to different manufacturing methods; they can be divided into single hooks and double hooks according to different shapes.

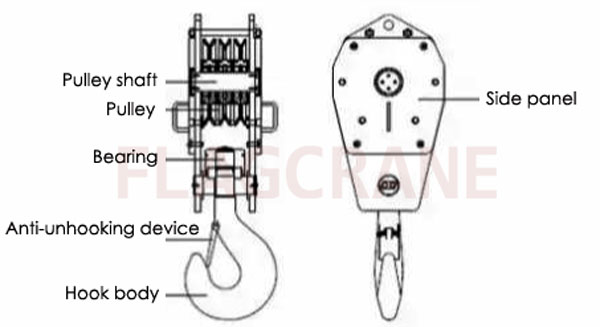

The schematic diagram of the common forged single hook structure is as follows:

Today we will introduce the two most common types:

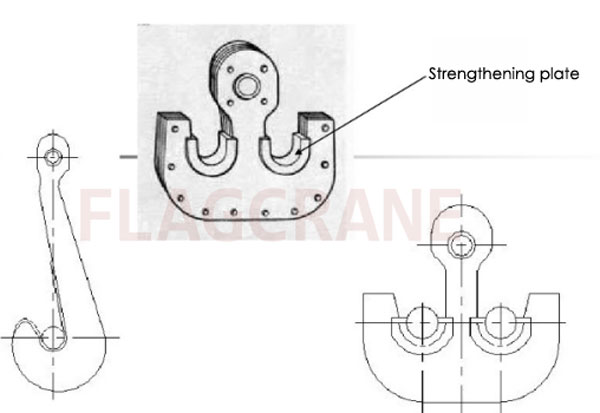

(1) Laminated hook

The laminated hook is divided into single hook and double hook. This type of hook has a simple structure, reliable operation and easy maintenance. Single hooks are mostly used on casting cranes, and double hooks are mostly used in general cranes over 100 tons.

(2) Forged hooks

Forged hooks are divided into single hooks and double hooks. Because the force on a single hook will be offset, it is not as favorable as the symmetrical force on a double hook. Therefore, small and medium-sized cranes below 75 tons mostly use single hooks, while large cranes above 75 tons mostly use double hooks.

II. How to do daily maintenance on crane hooks?

Daily maintenance of crane hook blocks?

The safety and stability of the hook block plays an important role in safe production. The user unit should regularly perform daily safety inspections and maintenance on the hook to ensure safe production. Generally speaking, daily inspections and maintenance of the hook include the following:

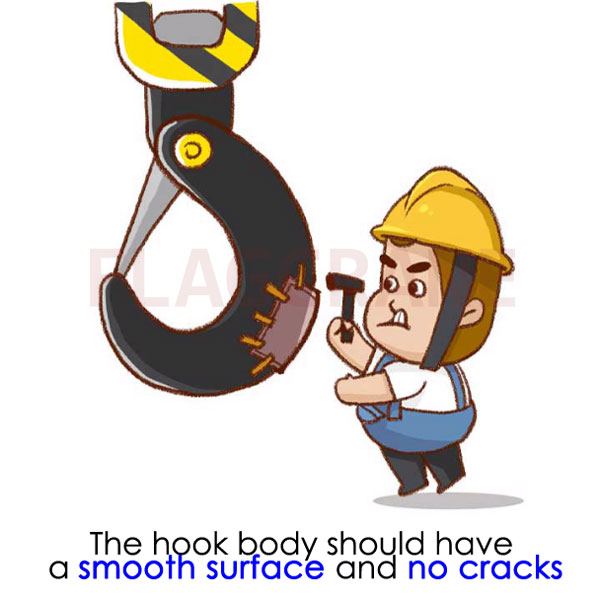

(1) Clean the crane hook assembly body with a non-corrosive organic solvent, wipe it dry and check it with a magnifying glass. If cracks are found, replace it immediately and do not perform repair welding.

(2) Check the crane hook opening and the amount of wear on the dangerous section.

(3) Check whether the pulley groove and rim are evenly worn, whether the wire rope matches the groove, and whether the pulley is loose or shaking.

(4) Ensure that the rotating part of the hook rotates freely and the gap cannot be too large. If it is difficult to rotate or stuck, check whether the bearing or sleeve is damaged or insufficiently lubricated.

(5) Check whether the main hook is damaged due to overload.

(6) Check the hook guard, crossbeam and other parts. If the guard is severely worn, it can be re-welded and re-bored. If a new part is replaced, it is necessary to ensure that the mechanical properties of the material meet the requirements.

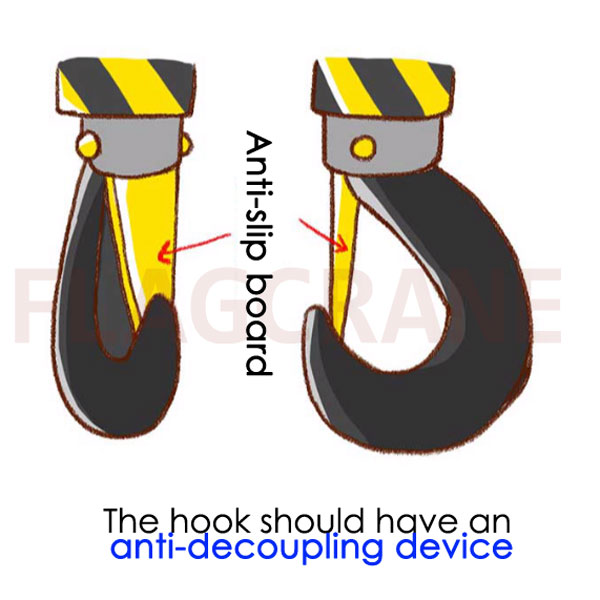

(7) Check the anti-unhooking device.

III. How to conduct regular inspections on crane hooks?

In addition, in order to ensure the safe operation of the lifting equipment in use, the crane hook needs to be inspected once every two years. Among them, casting cranes, tower cranes, elevators, and mobile cranes are inspected once a year, and they must be performed by full-time inspectors.

① Perform non-destructive testing on the parts where stress is concentrated on the surface of the workpiece. If cracks are found, stop using it immediately and replace it with a new hook.

② Regularly check the wear or corrosion of the dangerous section of the hook. When the actual size is less than 95% of the original basic size, the hook should be replaced with a new one.

③ When the hook body twist angle exceeds 10°, a new hook should be replaced.

④ When the hook opening deformation reaches 10% of the original basic size, a new hook should be replaced.

⑤ Repair welding is not allowed for defects on the hook.

⑥ Dangerous sections or hook handles must not have plastic deformation.