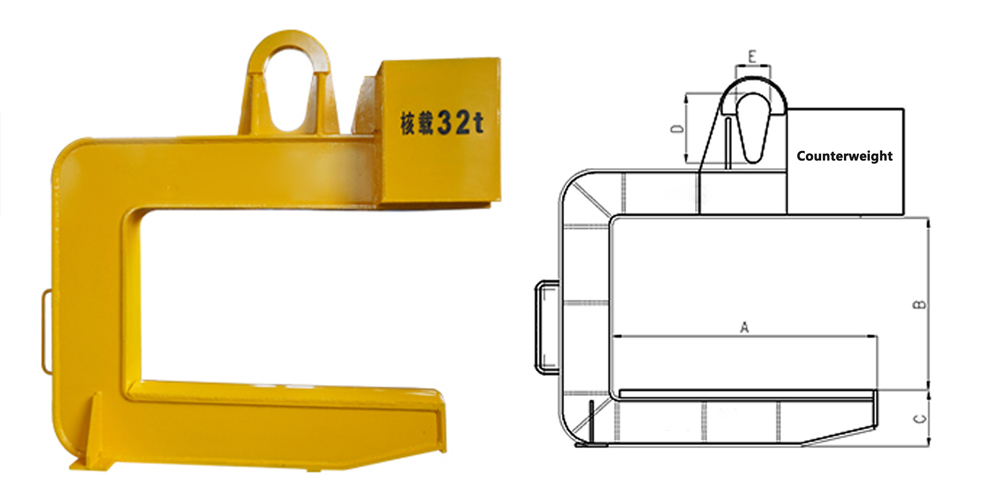

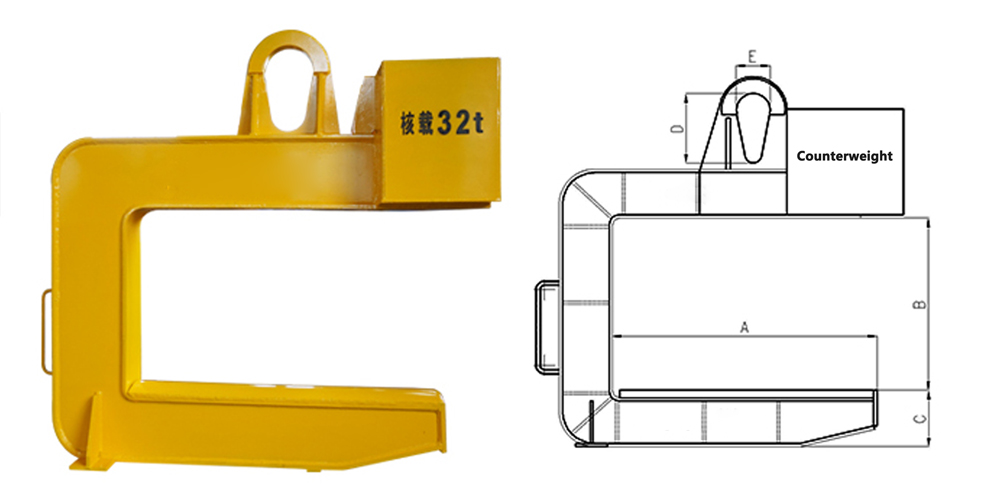

C-hook for Crane

C-hook for crane is mainly composed of hook main body and counterweight iron. The main part of the hook is made of Q355B steel plate (high-quality low-alloy steel) and steel pipe. The section is a box-shaped structure, which has good resistance to bending and torsion. The C-type hook has the characteristics of light weight and long service life. Various specifications and models of C-type hook flagcrane can be customized according to demand.