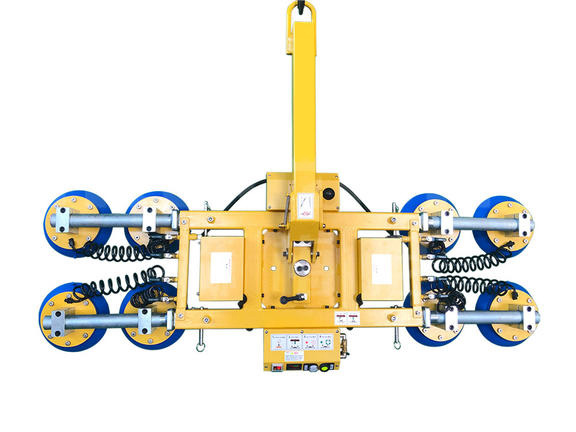

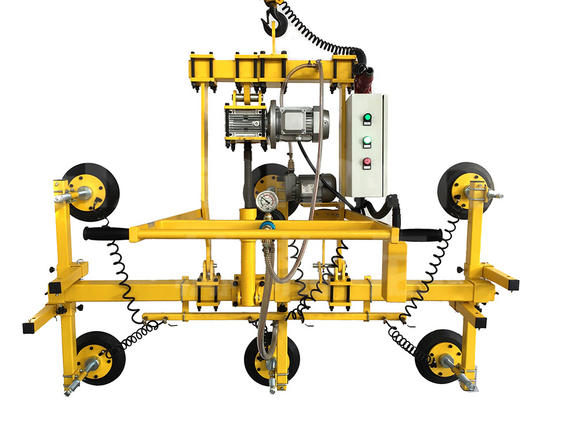

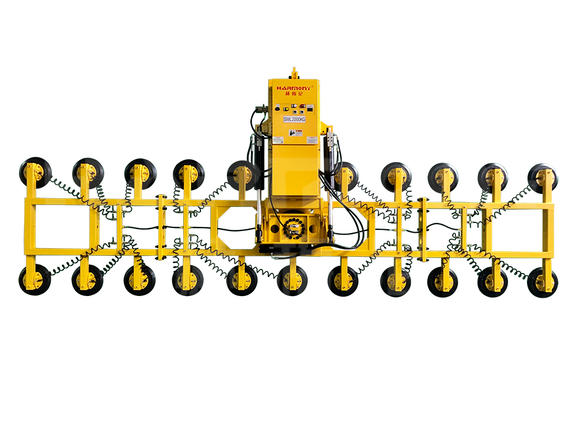

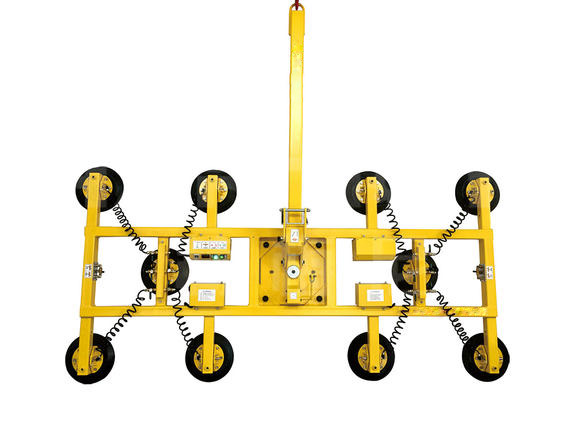

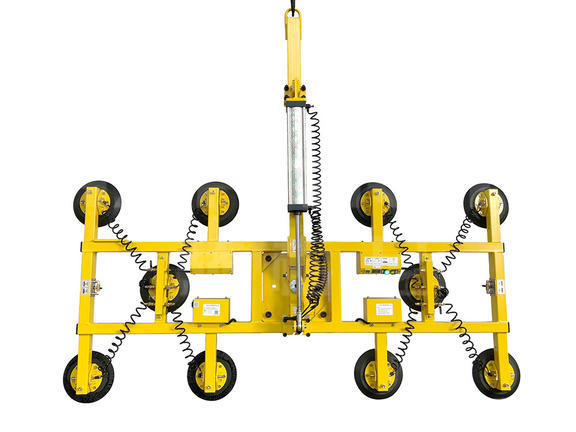

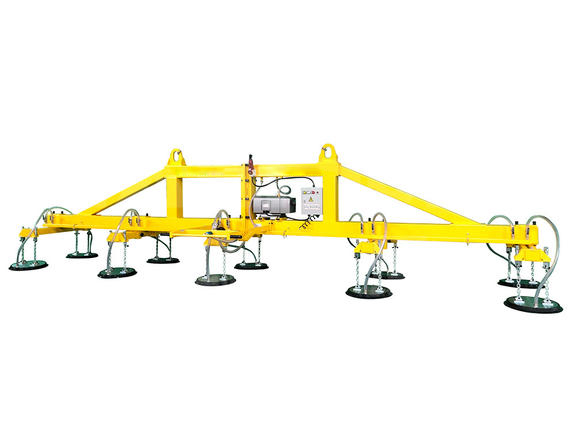

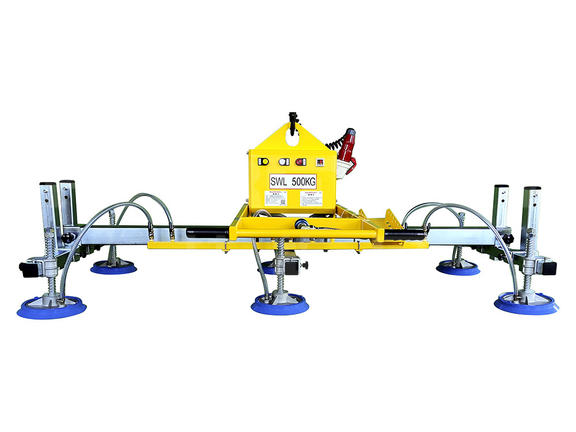

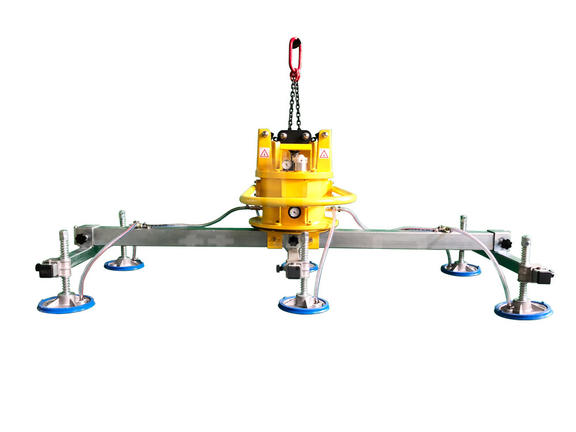

Vacuum Lifter

Vacuum lifters are almost omnipotent: whether you need to stack boxes, load barrels onto trucks, stack metal sheets or wood, or move stones or furniture - using a vacuum lifter for handling is always your best handling solution. Using a vacuum lifter for transportation is faster, more ergonomic, and safer.

Vacuum lifter is an automatic lifting equipment. It has the characteristics of speed, safety, and convenience. It utilizes the principle of vacuum adsorption, using a vacuum pump or vacuum blower as a vacuum source to generate vacuum at the pad end, firmly sucking various workpieces, and transporting them to the designate position through a rotatable mechanical arm or crane.

Flagcrane is orient to factory automation and vacuum intelligent handling, and provides one-stop service of design, planning, manufacturing, installation, training and after-sales service for mechanical processing, glass curtain walls, glass deep processing, food processing, aluminum products, laser processing, automobile manufacturing, packaging logistics, stone processing, solar energy and other fields.