Crane Hook Block

Flagcrane has developed series of crane hook block in accordance with the latest requirements and techniques FEM 1001 and DIN STANDARD 15020.

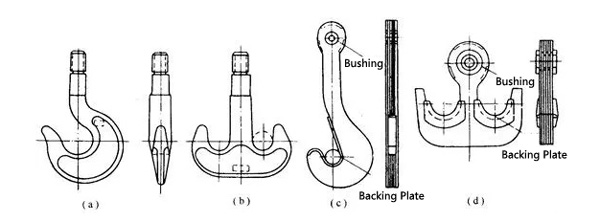

1. The crane hook block is generally made of DG20 steel and DG34GrMo alloy steel, which is forged, pressed, annealed and then machined. It has the characteristics of high strength, good plasticity and toughness.

2. The crane hook block is generally made of A3, 20# or 16Mn steel plate, the thickness is not less than 20mm, without sudden break, and the reliability is high.

3. Flaps of hook block are generally used in places with large tonnage in high temperature environments.

4. . All hooks will be equipped with safety latch to prevent the load from unhooking.

5. Ratio of pulley diameter and wire rope diameter is greater than 20 to ensure service life of rope.

6. A protective pad is set at the hook mouth to ensure that the hook mouth will not be damaged by the friction of the spreader and prolong its service life. The protective pad can be replaced when it is damaged.