Lifting Magnet / Lifting Electromagnet

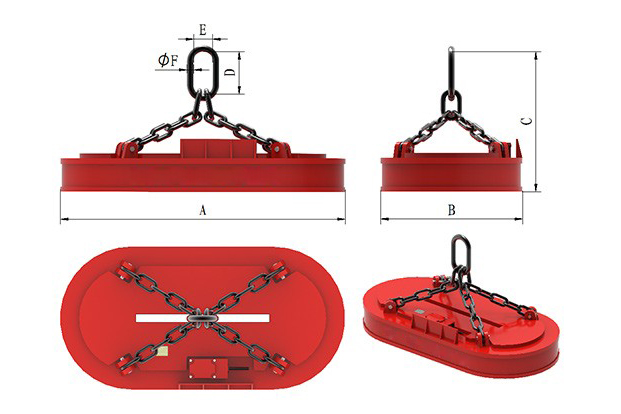

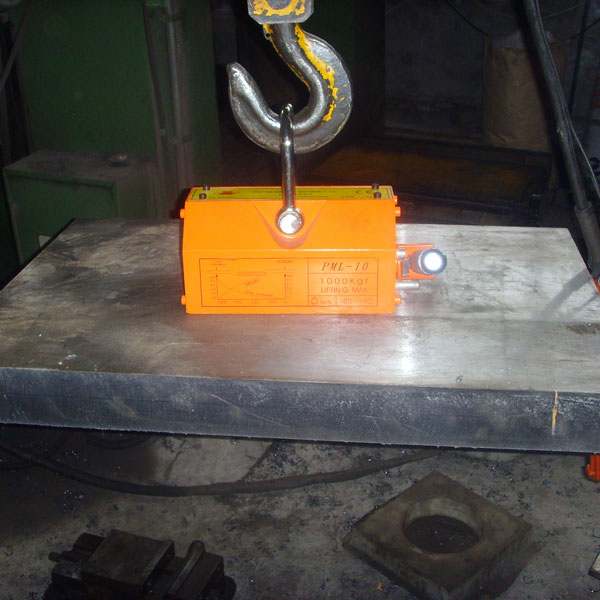

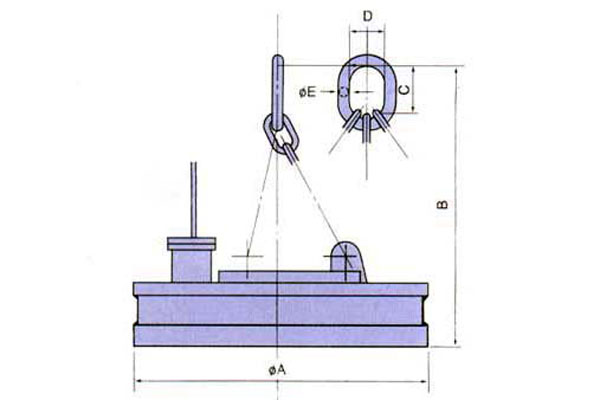

Lifting magnet / lifting electromagnet is a kind of special spreader that absorbs magnetic materials through electromagnetic. It is composed of a steel shell and an excitation coil inside the shell. It is widely used in metallurgy, mining, machinery, transportation and other industries, and acts as an important tool for handling heavy steel objects. At the same time, it can also be used in many applications such as electromagnetic manipulator, uncoiler, coking furnace cover and so on. According to different types of objects to be sucked, lifting electromagnets with various structures are designed in different categories, which are highly targeted.

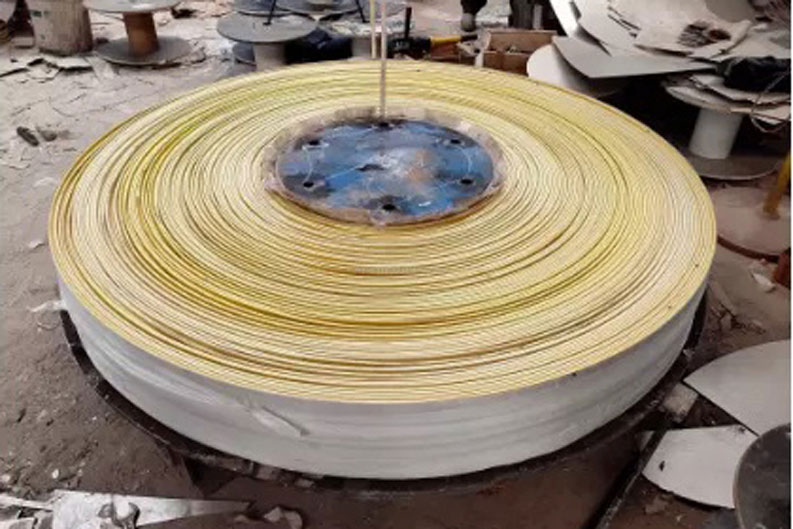

Flagcrane's lifting electromagnets are used in handling operations such as billets, round billets, steel plates, bundled bars, coiled wires, steel coils, and various types of scrap steel. Different lifting solutions are customized according to different steel plate profiles. No loss of magnetism, no damage to the workpiece, multiple electro-permanent magnet cranes can implement group control, saving time and improving work efficiency.