What are Types of steel coil lifting equipment?

In the production process of steel coils, steel coil lifting equipments are essential equipment, and they are widely used in the handling, loading and unloading, and storage of steel coils. Here are several common types of steel coil lifting equipment:

1. C hook: The C hook is the most common type of lifting equipment, which consists of a C-shaped hook and a suspension chain. The advantage of the C hook is that it is simple in structure and easy to use, and is suitable for handling and unloading smaller steel coils.

2. Electromagnetic sucker: The electromagnetic sucker is a lifting equipment that uses electromagnetic principles to suck steel coils. It is usually composed of a sucker and an electromagnet, and has the advantages of strong suction force and easy operation, and is suitable for handling and unloading larger steel coils.

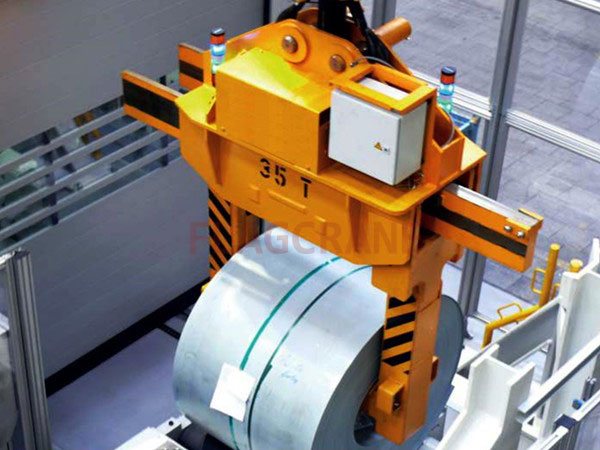

3. Lifting tongs: The lifting tong is a lifting equipment that clamps the steel coil by using the principle of the clamp. It is usually composed of two clamps, and has the advantages of strong clamping force and easy loading and unloading, and is suitable for handling and unloading larger steel coils.

4. Balance lifting equipment: The balance lifting equipment is a lifting equipment that uses the principle of balance to carry the steel coil. It is usually composed of a balance arm and a suspension chain, and has the advantages of stable carrying and easy operation, and is suitable for handling and unloading larger steel coils.

In short, in the production process of steel coils, different types of steel coil lifting equipment have their unique advantages and application scope, and the appropriate steel coil lifting equipment needs to be selected according to specific process requirements and site conditions.